6 manufacturing divisions offer over 60 modern technologies in a new large-capacity technological center built under one roof.

Quality and Speed Through Modern Manufacturing

Our manufacturing setup is designed to be economical, flexible, and fast. We combine traditional cardboard craftsmanship with modern automation and precise process management.

Technologies We Use

- Digital cutting plotters for models and mockups, up to 1600 x 1300 mm format.

- Manufacturing is carried out on several die-cutting machines and industrial production plotters up to 2200 x 1600 mm format.

- The automatic laminating machine works up to a maximum format size of 1060 x 1450 mm, as does the automatic gluing machine.

- We can enhance the product surface with lamination or varnishing.

- For packaging, we use an automatic packaging machine and stretch wrap machines.

- Quality control at every step – monitoring printing, die-cutting, construction, and final packaging.

Manufacturing Tailored to Your Project

For every project, we take the following into consideration:

- weight and type of product,

- required display lifespan,

- placement in the sales area,

- necessary print type and surface finish,

- requirements for compactness (storage) and transport.

The result is a solution that works while simultaneously taking the budget into consideration.

Support: consultation, advisory services, briefing process

Original design and development: from concept to specific solution, professional team of designers and engineers

Graphics, 3D design, sampling: data processing, 3D product preview, sample production

Pre-press: expert team, modern DTP studio, latest technology

Offset printing: format up to 1060 x 1450 mm, 5 printing colors + varnish

Modern UV digital printing: print width up to 2200 x 1600 mm

Modern UV flatbed: format up to 2200 x 1600 mm, 6 colors

Modern industrial plotters/cutters: format up to 2210×3200 mm

Die-cutting machines: format up to 1800 x 1300 mm

Laminating/mounting machines: format up to 1600 x 1450 mm

Automatic gluing, finishing operations: cutting, perforating, shape die-cutting, creasing, scoring, riveting, binding

Many surface finishing options: lamination, varnishing, lenticular printing, holographic foils

Plastic bending: max. width 1000 mm

Assembly, packaging: automatic packaging machine, co-packing

Warehousing: 7,500 m2 of storage and production space, continuous warehouse operation

Logistics: distribution gradually or simultaneously across the entire EU, fast and efficiently

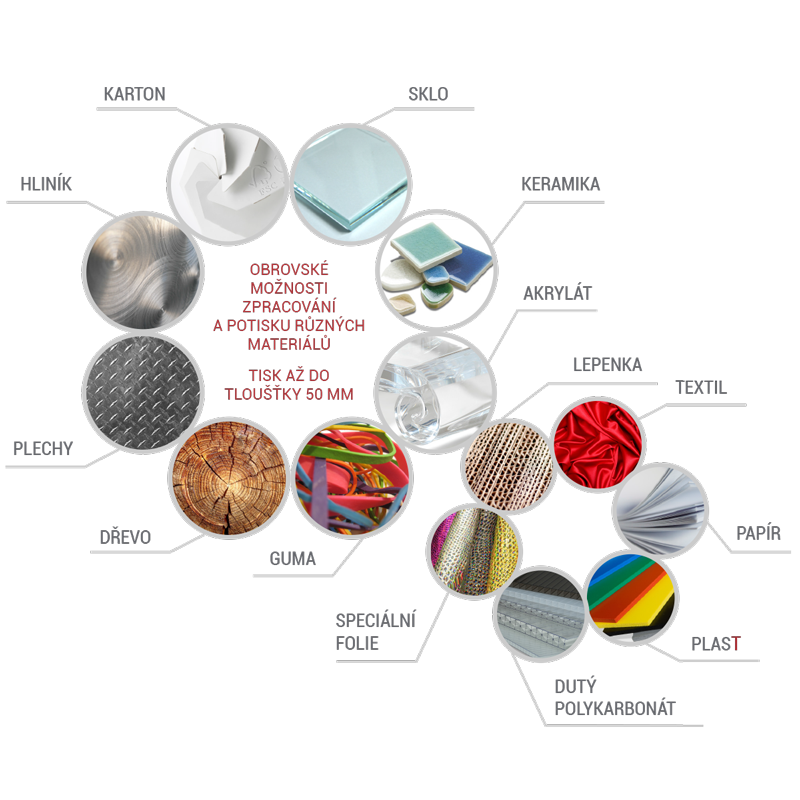

We Manufacture Using a Wide Range of Materials

We can produce and print on almost anything…

We Use the Highest Quality Inks

- Outdoor durability up to 3 years.

- Indoor durability of 5 years, or 10 years with lamination.

- Greenguard and EN 71 (Toy Standard) ink certifications.

- Completely non-hazardous to health (VOC FREE).

- Suitable for food contact, toys, and other children’s products.

- Excellent color fastness in sunlight.

- Excellent resistance to mechanical damage.

- Very fast drying = faster processing.