OUR

CATALOG

Technology

6 divisions - over 60 production technologies

New large-capacity technology center built under one roof.

Complete modern technological equipment allows us to independently produce a wide range of POP/POS products, mainly based on corrugated cardboard, textiles, plastics, aluminum and wood.

PRODUCTION DIVISION

- Tailor made 3D advertising

- Textile

- CartonagePOP/POS

- Presentation systems

- Large and small area printing

WE WORK ON THE MOST MODERN MACHINES, WHICH GUARANTEE:

- HIGH QUALITY

- CAPACITY

- SPEED

- COMPETITIVE PRICE

We have the entire production process under our own control.

From design, to production, to shipping.

BACKGROUND

- Consultation

- Advice

- Briefing process

ORIGINAL DESIGN AND DEVELOPMENT

- From concept to concrete solution

GRAPHICS, 3D DESIGN, MODELING

- Data processing

- True 3D preview

- Sample

PRE-PRESS

- Professional team

- Latest technology

MODERN APPROVAL PROCESS

- Online via web interface

OFFSET

- up to a 1600 x 1200 mm

- 5 colors + varnish

MODERN UV DIGITAL PRINTING

- width up to 2050 mm,

- thickness up to 40 mm

- 6 colors

MODERN UV FLATBET

- up to 3100 x 1600 mm,

- roll max. 2500 mm

- 6 colors

QUALITY UV PRINTING PLASTIC PAINT

- up to a 2500 x 1220 mm

ECO SUBLIMATION PRINTING

- up to a width of 1620 mm

MODERN INDUSTRIAL PLOTTERS

- up to a 2210 x 3200 mm

CUTTING MACHINES

- up to a 1800 x 1300 mm

LAMINATING MACHINES

- up to a 1600 x 1200 mm

AUTOMATIC GLUING, FINISHING OPERATIONS

- cutting, perforating, shaped

- cutout, bigging, grooving,

- riveting, ties, etc.

MANY OPTIONS FOR SURFACE TREATMENTS

- lamination, painting

- lenticular printing, holographic films, etc.

3D VACUUM FORMING OF PLASTIC

- up to a 800 x 1400 mm

PLASTIC BENDING

- max. width 1800 mm

HIGH FREQUENCY WELDING

- up to a 800 x 1400 mm

THREE-AXIS MILLING CUTTER

- up to a 1300 x 2500 x 200 mm

LASER

- up to a 1300 x 2500 mm

STRING CUTTER

PROFESSIONAL SEWING AND EMBROIDERY MACHINES

COMPLETION, PACKAGING

- Automatic packer

- Copacking

STORAGE

- 6000 m2 of storage and production space

- Continuous operation

LOGISTICS

- Distribution gradually or all at once

- Within the entire EU

- Quickly and efficiently

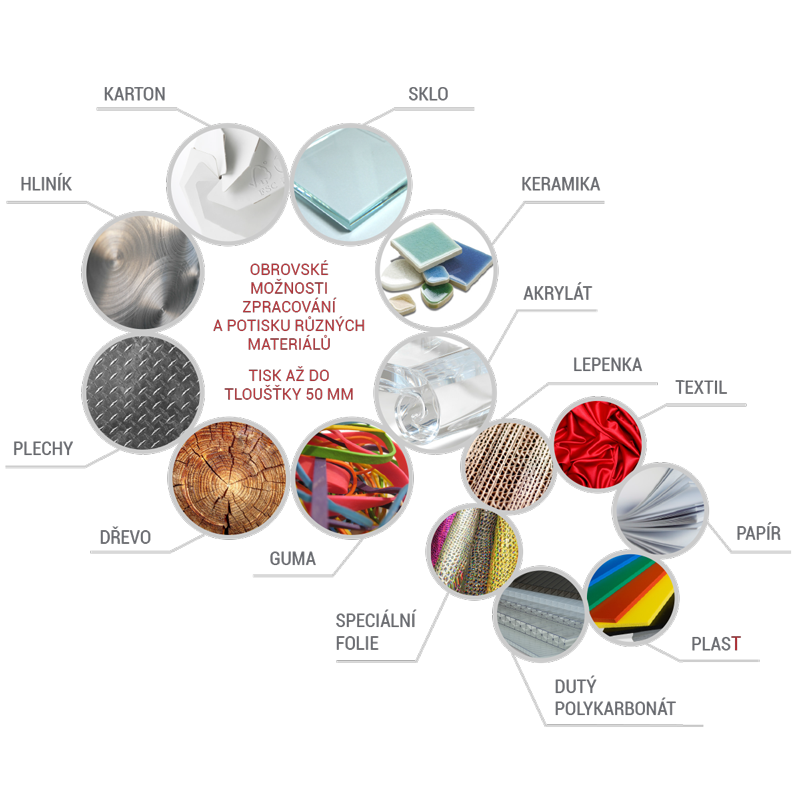

We manufacture from a wide range of materials

We will make and print almost anything.

We use the highest quality paints

- EXTERIOR LIFETIME UP TO 3 YEARS.

- INTERIOR LIFETIME 5 YEARS, WITH LAMINATION 10 YEARS.

- INKS CERTIFICATE:

- GREENGUARD, EN 71 (Toy Standard)

- absolutely harmless to health (VOC FREE)

- suitable for contact with foodstuffs, toys and other products for children

- EXCELLENT COLOR FASTNESS IN THE SUN

- EXCELLENT RESISTANCE TO MECHANICAL DAMAGE

- VERY FAST DRYING = FASTER PROCESSING

Production of pos/pop

We use cardboard plotters for models, mock-ups and low-cost series up to a format of 2500 x 1600 mm.

Production is carried out on several die-cutting machines and industrial production plotters up to a format of 2200 x 3200 mm.

Automatic laminating machine up to a maximum format size of 1600 x 1100 mm, as well as an automatic gluing machine.

We can polish the surface of the products by lamination or varnishing.

For packaging, we use an automatic packer and machines for wrapping in stretch film. We can also make packaging for our products.

Vacuum forming - special 3D pop/pos

We own both vacuum forming technology for the production of 3D plastic POP/POS media, as well as digital technology capable of printing them without problems.

In 3D, we produce e.g. toppers or sides of your displays, Wobblers, Shelf Talkers, hanging POS, counter or cash register stands, various HoReCa stands, posters, coin boxes, 3D mock-ups of products, 3D advertising items, etc.

- An extensive assortment - everything from towels, through T-shirts, jackets to work clothes.

- A wide range of materials - from cotton to various sports and outdoor functional materials in different weights and surface treatments.

- The most modern sewing and embroidery machines.

- We use only quality SERICOL paints.

- Quality printing - We print a wide range of textiles and textile-based materials. Several different types of machines with different printing principles allow us to find printing solutions for almost any textile.

Textile factory

Textile printing based on dispersion sublimation printing is a real dyeing of the textile. It is a two-phase printing method, where colors are first applied to the surface of the material and then fixed into the material at high temperature. During the fixation process, the color first evaporates in the microstructure of the fabric at a temperature of 200°C, and immediately after that these vapors are absorbed by the fibers from which the textile is woven. It means that this method of printing does not mean applying color to the surface of the fabric, but coloring the individual fibers of its structure.

Gallery

Certificate of Incorporation

CATEGORY

CARDBOARD BOX POP/POS

INFORMATIONS

OTHERS

INQUIRY

© 2023 SAGLIF GROUP a.s. | All rights reserved